Reaction Calorimetry

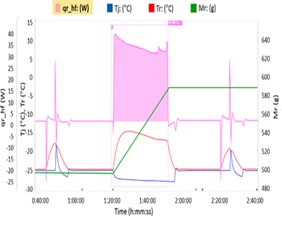

Heat flow calorimetry allows the user to measure heat whilst the process temperature remains under control. While the driving force Tr − Tj is measured with a relatively high resolution, the overall heat transfer coefficient U or the calibration factor UA respectively, is determined by means of calibration before and after the reaction takes place. The calibration factor UA (or the overall heat transfer coefficient U) are affected by the product composition, process temperature, agitation rate, viscosity, and the liquid level.

Control Modes-Heat flow

Specifications

- Temperature Range −70 °C to 300 °C

- Heating/Cooling Fast heat transfer media circulation with split heating and cooling loop for effective and precise temperature control

- Heating Power Up to 4 kW

- Cooling Power Up to 6 kW

- Volume Range/Reactors 100 mL to 22 L Glass, AISI316, Alloy C-22

- Pressure Range Vacuum to 60 bar (depending on reactor)

- Calorimetric Measurement Heat flow and real-time calorimetry • Isothermal • Non-isothermal • Adiabatic • Reflux conditions

What data we get?

- Heat of reaction

- Adiabatic temperature rise (ΔTad)

- Maximum temperature in synthetic reaction (MTSR)

- Amount of gas liberation

- Specific heat (Cp)

- Heat transfer coefficient (U)

- Thermal accumulation (%)