An efficient and a systemic way designed to identify and analyse hazards that are related with the processing or handling of highly hazardous materials and to recommend actions to eliminate hazards. PHA is a proactive and structured approach by chemical process operations to understand what can go wrong, how likely it is to go wrong and what steps are necessary to prevent or mitigate undesired consequences.

The goal of performing process hazard analysis is not to label a safe process, but is to detect unsafe situations and to implement the necessary safety improvements to minimise risk

• PHA can identify the potential causes and consequences of fires, explosions and releases of toxic chemicals as well as the other factors which might affect the process like equipment, instrumentation, human actions and etc.

• The hazards related to the process

• Engineering and administrative controls for the implemented process

• The consequences of failure of engineering and administrative controls

• Facility siting

• Human factors

• The range of possible safety and health effects caused by the failure of controls.

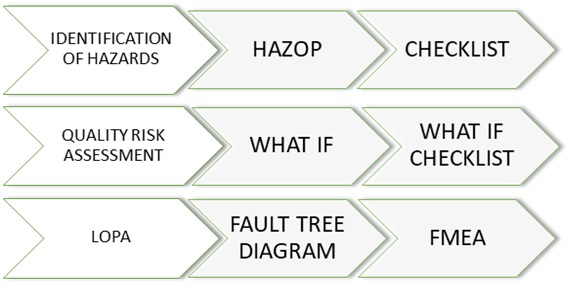

A variety of process hazards analysis techniques are available. Some of them as per OSHA PSM regulation 29 CFR 1910.119:

• Checklist

• What-if

• What-if Checklist

• Hazards and Operability Study (HAZOP)

• Fault Tree / Logic Diagram

• Failure Modes and Effects Analysis (FMEA)

• LOPA & QRA

Why PHA is that much important to perform!

• Avoiding accidents before they happen: Effective PHA can establish accident/hazard free process pathway. The goal of modern safety engineering is to prevent accidents before they happen unlike the past, some safety engineers would be content to wait for an accident to happen; then they would implement rules and regulations to prevent the same accident from happening again. The major flaw with this type of reasoning is that a certain number of accidents must be allowed to happen before unsafe behaviour can be changed. PHA is the tool to use to accomplish this goal.

• The cost of accidents vs. the cost of hazards analysis: Hazards analysis can be costly up front. However, if the process is accident free (as a result of an appropriate hazards analysis) the hazards analysis is profitable and cost-effective.

“The cost of accident and recovery from the accident pays a way more than effective PHA”.

• protect from major equipment damage

• Prevent release and personnel exposure to hazardous chemicals.